Fired Heater Burners

API 560 and API 535 are typical standards used to design process heaters and are titled “Fired Heaters for General Refinery Service” and “Burners for Fired Heaters in General Refinery Services” respectively. They both define a process heater burner as a device that “introduces fuel and air into a heater at the desired velocities, turbulence, and concentration to establish and maintain proper ignition and combustion.”

Some of the typical applications for fired heaters where process burners are installed include:

- Crude Distillation Furnaces

- Vacuum Distillation Furnaces

- Coker Furnaces & Visbreakers

- Reformers/Platformers

- Ethylene Furnaces

- Cracking Furnaces

- Hot Oil Heaters

- Reboilers

- Reactor Charge Furnaces

- Catalyst Regen Heaters

The three basic burner types are premix burners, nozzle mix burners, combination burners.

In a premix burner

the fuel and air are mixed prior to entering the combustion zone. The benefits of the premix burner design are that premix burners promote good fuel/air mixing which tends to shorten flame length. Premix burners also automatically adjust air flow with varying fuel rates. As the fuel gas pressure increases or decreases, the gas velocity through the mixing orifice follows resulting in the appropriate change in air flow. This reduces the need for operators to adjust air registers as firing rates go up and down. One of the disadvantages of a premix burner is that they can be susceptible to flame flashback, particularly at turndown conditions or when burning fuels with high flame propagation speeds. Fuel gases containing high amounts of hydrogen are the most common example of fuels with high flame propagation speeds. If the exit velocity of the fuel/air mixture drops too low, the flame will propagate back and stabilize inside the burner. Flame flashback reduces heater efficiency, creates noise problems, and if left uncorrected can damage or destroy the burner.

In a nozzle mix burner

the gas and air are kept separate until entering the combustion zone. This eliminates the possibility of flame flashback. These burners have higher turn down ratios and are typically better suited for multiple fuel gas compositions. The flame envelope is longer than comparable heat release premix burners and adjustments to the air registers must be made manually or through actuated air registers on instrument control.

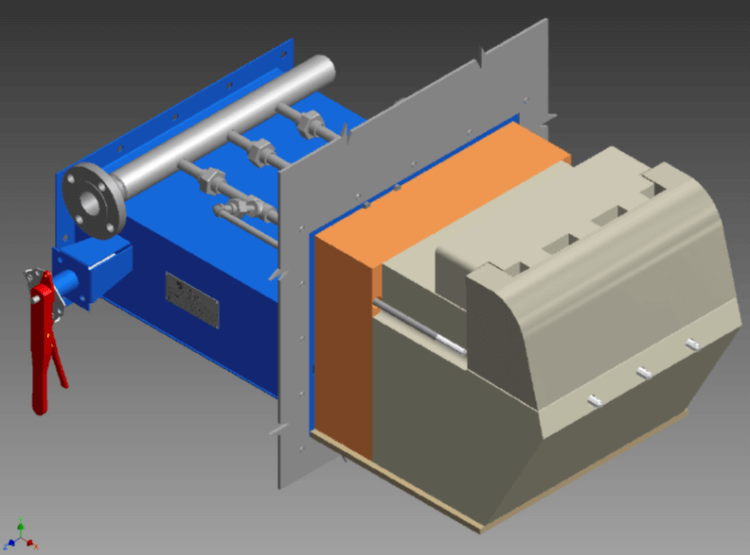

A combination burner

is a burner designed to be capable of burning fuel gas and/or fuel oil. When burning fuel oil it is necessary to atomize or vaporize the liquid fuel. Atomization can be done mechanically or by using a steam atomizing gun. To vaporize liquids, large volumes of heated air are mixed with the liquid particles prior to entering the combustion zone.

As environmental regulations have become more stringent, burner technologies had to be developed to meet the lower NOx emissions limits. The next few paragraphs discuss the two mechanisms by which NOx is formed in burners and the basic concepts behind the various generations of low NOx burners.

The two mechanisms by which NOx are formed in process heater burners are Chemical NOx and Thermal NOx.

Chemical NOx

is created when fuels containing “bound nitrogen” are burned. Ammonia (NH3) and Hydrogen Cyanide (HCN) are examples of fuel components with bound nitrogen. For clarification the nitrogen contained in air (N2) is considered inert and not contributor to chemical NOx. When burned, all of the bound nitrogen atoms in the fuel gas convert to NOx. Currently the only ways to reduce chemical NOx are to remove the nitrogen bearing fuel components prior to combustion or use post combustion treatments like SCRs or SNCRs. Current burner technologies do not mitigate chemical NOx.

Thermal NOx

created inside the flame envelope where the core flame temperature is the highest. The majority of nitrogen (N2) in the combustion air passes through the burner unchanged; however, a small amount of nitrogen gets exposed to the peak flame temperature and breaks down creating nitrogen free radicals. These free radicals react with the oxygen in the combustion air to create thermal NOx. A typical natural draft, nozzle mix burner can create 100ppm of NOx in the flue gas.

For many years, burner manufacturers have been developing designs to safely lower the core flame temperature and thereby reduce the amount of thermal NOx created by the burner. Burner designers first started developing staged air and staged gas burners. Staging means to introduce the fuel gas and/or air at different points creating primary and secondary combustion zones. This stretches the flame out and reduces the peak temperature inside the flame. This generation of burners is often collectively referred to as “low NOx burners.” This generation of burners reduced thermal NOx production to approximately 50ppm.

The next big innovation was internal flue gas recirculation burners. These burners are often referred to as “ultra low NOx burners” or” 2nd Generation ultra low NOx burners.” These staged gas burners take advantage of the flue gases that circulate inside the heater. The burner pulls the “cooler” flue gases into the combustion zone. This further cooled the core flame temperature reducing thermal NOx production in a natural draft burner to 25 ppm in many applications.

The latest burner technologies on the market today are referred as “next generation ultra low NOx burners.” These burners use many of the concepts described above with advanced burner tile designs and burner tip arrangements.