New Fired Heaters

When a user is considering a new heater, either to debottleneck a process or to add new capacity, or to replace an existing heater, proper design is essential. A good heater designer will consider the reliability, efficiency, runtime, and emissions targets for the heater in their design. Great Southern has some of the best process designers in the business.

API vs Non API Design

Whether you require an API 560 fully-compliant design, one that follows industry standards, or somewhere in between. Great Southern can work with customer provided specifications, or provide optimization recommendations, to ultimately design the best heater for your application. API 560 addresses many aspects of a heater, for the latest information, please contact us today.

Things to consider when building a new heater:

- Number of fluid passes

- The tube coil size and material

- Fluid information (Type, Composition, pressure and temperature)

- Heat Flux Loading, heat split between radiant and convection section

- Burner Data

- Draft requirement

- Instrument data needed

- Exterior data (Ladders and platforms, locations for slight doors)

- Downstream

- Midstream

- Heater Doors

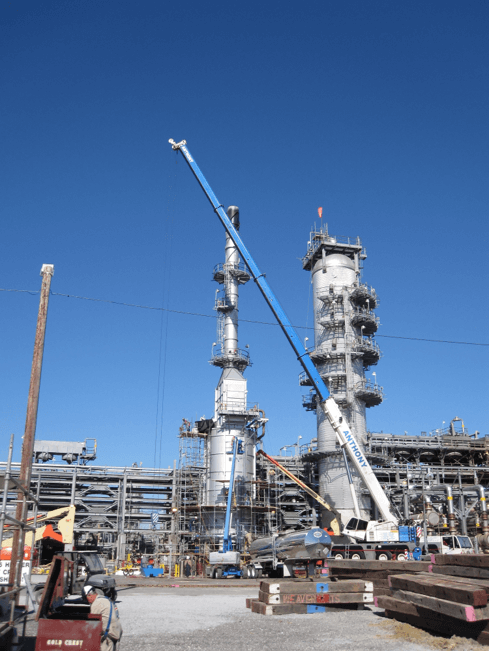

Downstream

- All Refinery and Petrochemical, including speciality black oil services

- Capable of designing and constructing up to full API 560 standards

- In-house CFD to aid in design

- 3D heater modeling

- Great Southern team has 100+ years of combined experience in new heater design and rebuilds

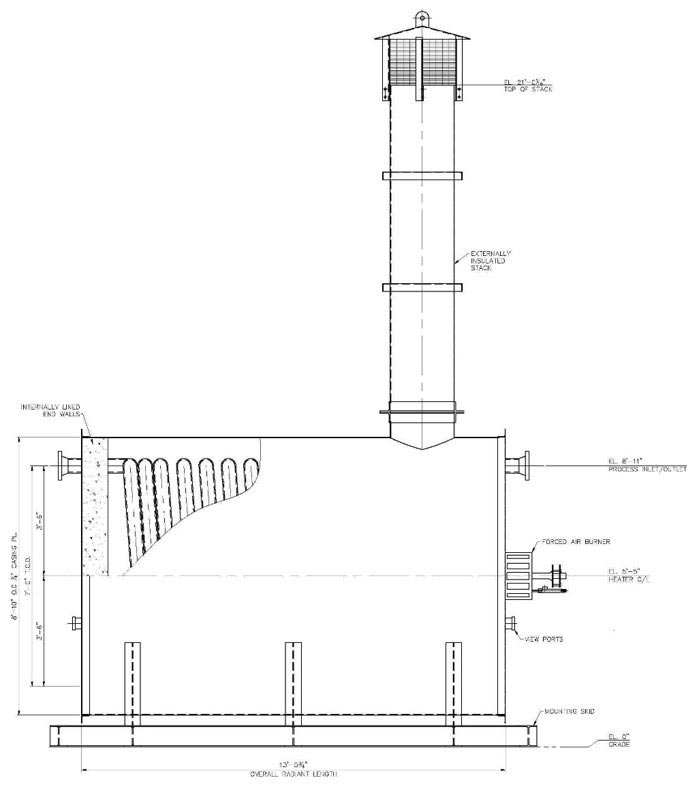

Midstream

- Ultra-Low NOx and CO emissions capable with no SCR needed

Typically between 1-70 MMBtu/hr - Skid mounted and fully assembled for quick delivery and install

- Horizontal helical tightly wound radiant section

- Forced air fully automated burner package

- Convection section available per design requirements for process or external heating

- BMS can be included with burner assembly

- Flanged heater terminals

Heater Doors

- Comes standard on new heaters, can be customized to sites needs (eg. glass can be removed)

- 5″ X 9″ and 8″ X 16″ cast heater sight doors (custom sizes available)

- Tight seal heater sight ports for improved heater efficiency and reduced NOx emissions

- High temperature glass permits viewing the burners without air leakage (Door can be provided without glass depending on customer need). Glass is resistant to clouding.

- Lightweight: 45 lb to 57 lbs

- Double-hinged design allowing door body and glass to be opened for IR scanning and cleaning of inside glass surface.

- Insulated stainless steel shutter to protect glass from direct radiant heat and limit soot build-up